- The Association of American Railroads plans to install approximately 1,000 new heat detectors on lines, which are a focus in current Norfolk Southern derailment investigations.

- BRS, the Brotherhood of Railroad Signalmen, is the union tasked with installing these detectors.

- Its president tells CNBC that workforce reductions in recent years have brought the construction crews responsible for this work down to 40% of its overall capacity.

The Association of American Railroads has announced several key safety measures for freight rails in the wake of the Norfolk Southern derailments, including the installation of approximately 1,000 new heat detectors, but a key union handling the construction work on lines says it lacks the workers to get the job done.

The president of the Brotherhood of Railroad Signalmen, in charge of the "hot box" detector installation, tells CNBC the reduction in the workforce over the last three years as a result of the precision scheduled railroading model used by Class I freight rails, coupled with the additions in tech and equipment, have created a workload issue.

We've got the news you need to know to start your day. Sign up for the First & 4Most morning newsletter — delivered to your inbox daily. Sign up here.

"Adding 1,000 more wayside detectors will create more work in the craft," said Michael Baldwin, president of the Brotherhood of Railroad Signalmen. "Our organization makeup right now is 60% in maintenance, and 40% in construction. The construction side of our membership is in charge of installing these detectors. We need more people. I've been in meetings with the Class I railroads and I can tell you they are attempting to hire. The problem is they are only retaining 40-50%. People are leaving during the training."

There are over a dozen different types of wayside detectors, including the hot-boxes which detect overheated bearings, axles, or other rail car components, which have been a focus of the ongoing Norfolk Southern derailment investigation in East Palestine, Ohio. There is no federal mandate for detectors, including the hot box detector, to be inspected. The Federal Railroad Administration recently released an advisory on the maintenance of hot box detectors and how they can better collect and review the data.

The AAR described its moves as an "initial set of steps" toward a future "with zero incidents and zero injuries — one where what happened in East Palestine never happens again."

Money Report

An AAR spokeswoman noted that with no federal regulations for detectors, "that is all a voluntary industry effort."

Baldwin said construction workers in the union currently keep log books on the maintenance they are doing "on their own," and any new regulations mandating inspections and proper maintenance would require additional workforce.

"We need signalmen numbers back," he said.

For one, he said Norfolk Southern needs to reestablish "electronic leader" positions, which hold a large portion of the responsibility for working with these detectors. "Three years ago, Norfolk Southern employed five in the area that includes East Palestine. Today there are zero," Baldwin said. "This position requires years of experience. Now the role has been transferred to the signal maintainer who is tasked with keeping up with the government-mandated tests of other equipment. To do this correctly you need to have a larger trained workforce."

Norfolk Southern said in a statement to CNBC that it regularly evaluates personnel needs for maintenance and inspection based on new equipment being installed as well as other operational changes. "Norfolk Southern has hired and trained more than 150 new signal employees, and we continue to hire. We are committed to the safety and integrity of our defect detectors," said Connor Spielmaker, Norfolk Southern spokesman.

The NTSB's preliminary report indicated that the wayside defect detectors worked as designed, though NTSB indicated in the report that "NS use of wayside defect detectors" remains among the issues in its ongoing investigation. Norfolk Southern announced a plan this week to study hot bearing detectors, including a reevaluation of the distance between them, and adding as many as 200 hot box detectors with the first installed near East Palestine. It also has implemented new safety measures related to train length.

An AAR spokesperson told CNBC the industry has a track record of making the necessary staffing decisions. She cited the recent focus on hiring train and engine employees, up 9.9% in January compared to the prior year. Total Class I freight rail employment in January 2023 was 119,245, up 6.7% (7,491 employees) over January 2022. Staffing levels have been a recent issue in clashes between rail management, unions and government agencies which oversees the major freight lines.

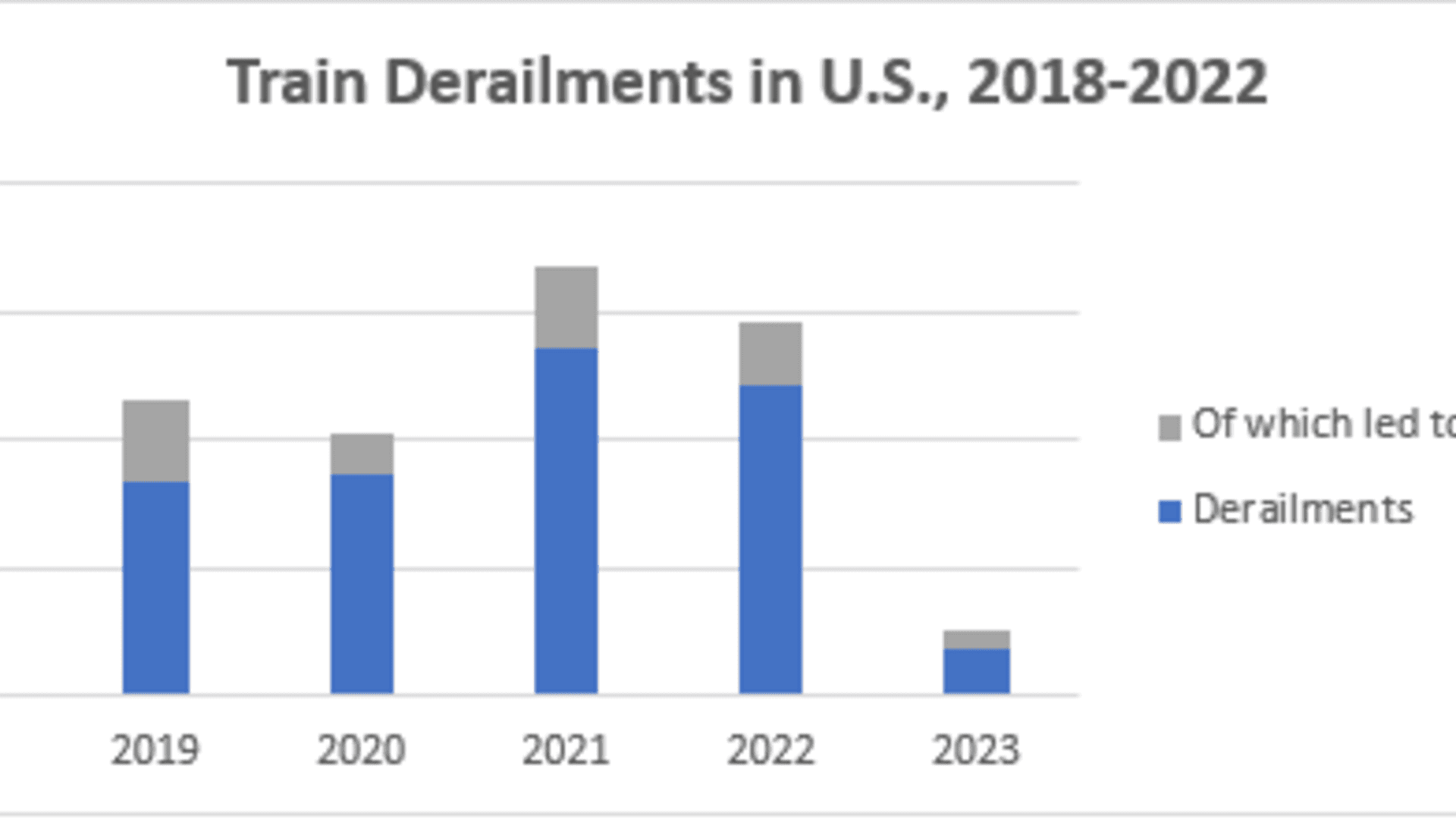

She also noted that over the last ten years, less than 1% of all train accidents have resulted in a hazmat release.

Derailments across rail companies, though not chemicals incidents specifically, have increased in recent years, according to Everstream Analytics.

"There is concern that freight trains in the U.S. are becoming longer, heavier, and faster while safety regulations have not been updated to meet such changes," said Jena Santoro, manager of intelligence solutions at Everstream. She added many freight rail companies reduced their number of safety inspectors as a cost-cutting measure in 2020, and despite a rebound in cargo volumes, companies have not yet returned to pre-pandemic staffing levels. "As such, the margin of risk has gotten thinner for rail companies when transporting cargo, and the oversight needed to ensure such risk is managed remains insufficient," she said.

The Department of Transportation recently called for the deployment of new inspection technologies, but also specifically called out the railroads for attempting to replace human inspectors with automated solutions. "The removal of human inspections has been a top priority for the rail lobbyists. Recent waiver requests around technology like Automated Track Inspection (ATI) have been framed by industry to set up a false choice between technology and human oversight. We need both to keep our nation's railroads safe," the DoT said.

A report last December from the Government Accountability Office found a 28% decline in staffing levels in the decade through 2021 among the largest freight railroads, a period of time during which the length of trains increased.

Ian Jefferies, CEO of AAR, stated in its release on the new safety measures that the industry has a "long history of voluntarily employing safety measures that go above and beyond federal requirements proves our belief in that principle. While we will continue to follow the National Transportation Safety Board's ongoing investigation in Ohio closely and recognize its deliberate, methodical, and fact-based approach, railroads are committed to taking appropriate steps now."

This story has been updated to include comment from Norfolk Southern.